TRANSFORMER.

KECL Transformer is naturally oil and air cooled, suitable for indoor/outdoor core type power and distribution transformer. We deliver top quality transformer and substation equipment. Generally 11/0.415KV voltage in distribution transformer otherwise as per customer requirements. Designed for transmission and distribution of A.C electric power of frequency 50Hz, 3 Phase. Core is the very important material and constructed from low-loss, COLD ROLLED GRAIN ORIENTED (CRGO) Electrical steel laminations insulated on both sides mostly imported from Korea, the Germany, and Europe. The core cut as an angle of 90 for rectangular shape, and also cutting V. the conductor insulation has a high dielectric strength. Super enamel insulation wire is used for HT winding. Copper strip insulated with pure cellulose paper used for LT winding.

Transformer Testing.

- Ratio, Polarity and Phase Relation Test.

- Insulation Resistance Test.

- No load Test (Open circuit test)

- Full load test (Short circuit test)

- Vector group Test.

- High Voltage Test.

- Oil dielectric strength Test.

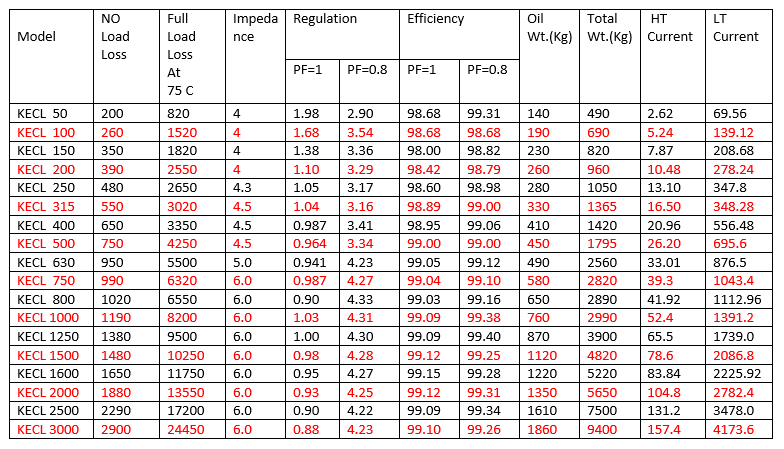

TECHICAL INFORMATION OF TRANSFORMER

TRANSFORMER CORE

Transformer Core, is specialty steel tailored to produce certain magnetic properties, such as a small hysteresis area (small energy dissipation per cycle, or low core loss) and high permeability. The Transformer steel can be also called lamination steel, silicon electrical steel, silicon steel or electrical steel. The material is usually manufactured in the form of cold-rolled strips less than 0,23 to 0,35 mm thick for Grain Oriented ant up to 0,5 mm fon Non Oriented grain steel. These strips are called laminations when stacked together to form a core. Once assembled, they form the laminated cores of transformers or the stator and rotor parts of electric motors. Laminations may be cut to their finished shape by core cutting lines punch and die.

Having any long cherished dream for your dream projects?

Share us your dreams, and let’s work together to make your dream come true.

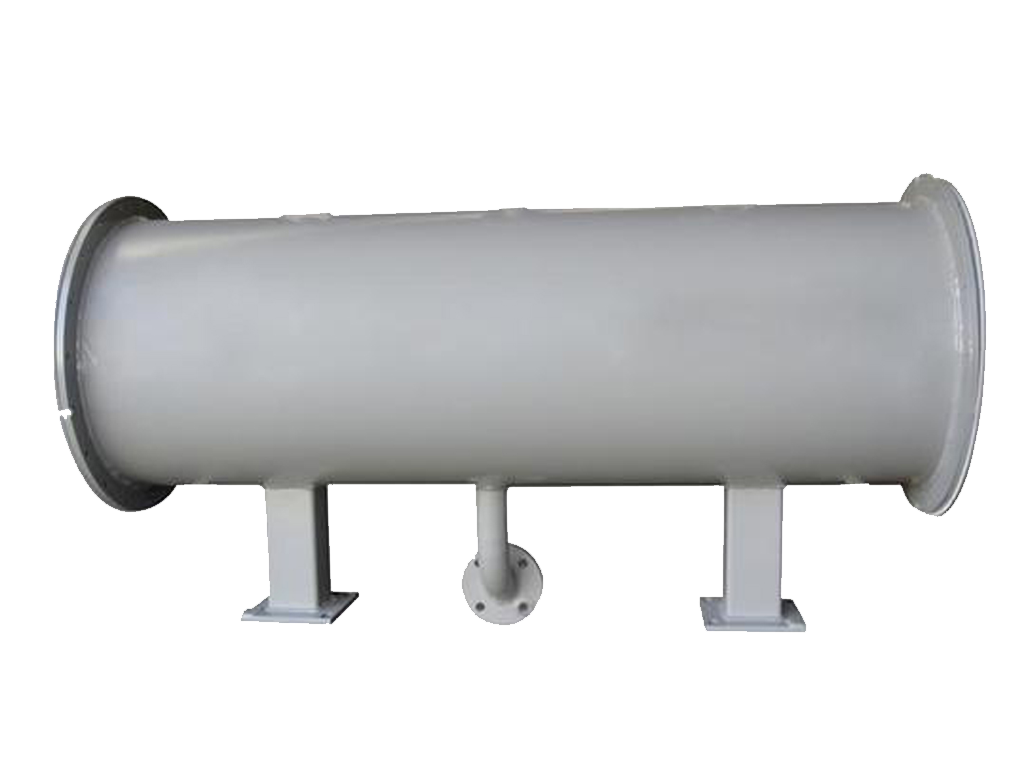

CONSERVATOR TANK

When volume of transformer insulating oil increases due to load and ambient temperature, the vacant space above the oil level inside the conservator is partially occupied by the expanded oil. Consequently, corresponding quantity of air of that space is pushed away through breather. On other hand, when load of transformer decreases, the transformer is switched off and when the ambient temperature decreases, the oil inside the transformer contracts. This causes outside air to enter in the conservator tank of transformer through silica gel breather

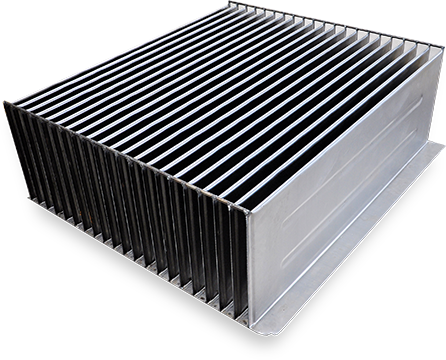

TRANSFORMER RADIATOR

Radiator is a bank of hollow pipe line which is used to transfer the thermal energy from one medium to another for the purpose of cooling. Some Bank are used at the power transformer for cooling the transformer oil as well as reduces the winding temperature under loading condition. The radiators are connected to the transformer through pipe line at all side of the transformer. small Transformer radiator two side.

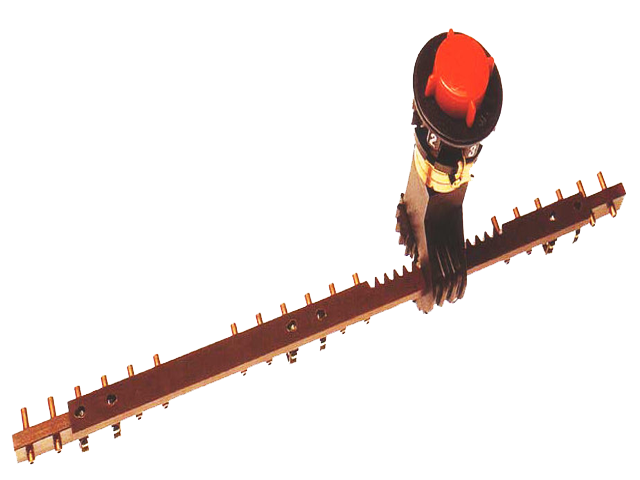

TAP CHANGER

A tap changer is a mechanism in transformers which allows for variable turn ratios to be selected in discrete steps. And with this mechanism obtain this variable turn ratio by connecting to a number of access points known as taps along either the primary or secondary winding. Tapping are adjusted by off circuit tap changer in case of distribution transformer of 11 kv class assembled on the top of core coil assembly.